What is a Spaghetti Diagram?

Spaghetti Diagrams in Warehousing & Distribution Flow

A Visual Tool to Reduce Waste and Improve Efficiency

What is a Spaghetti Diagram?

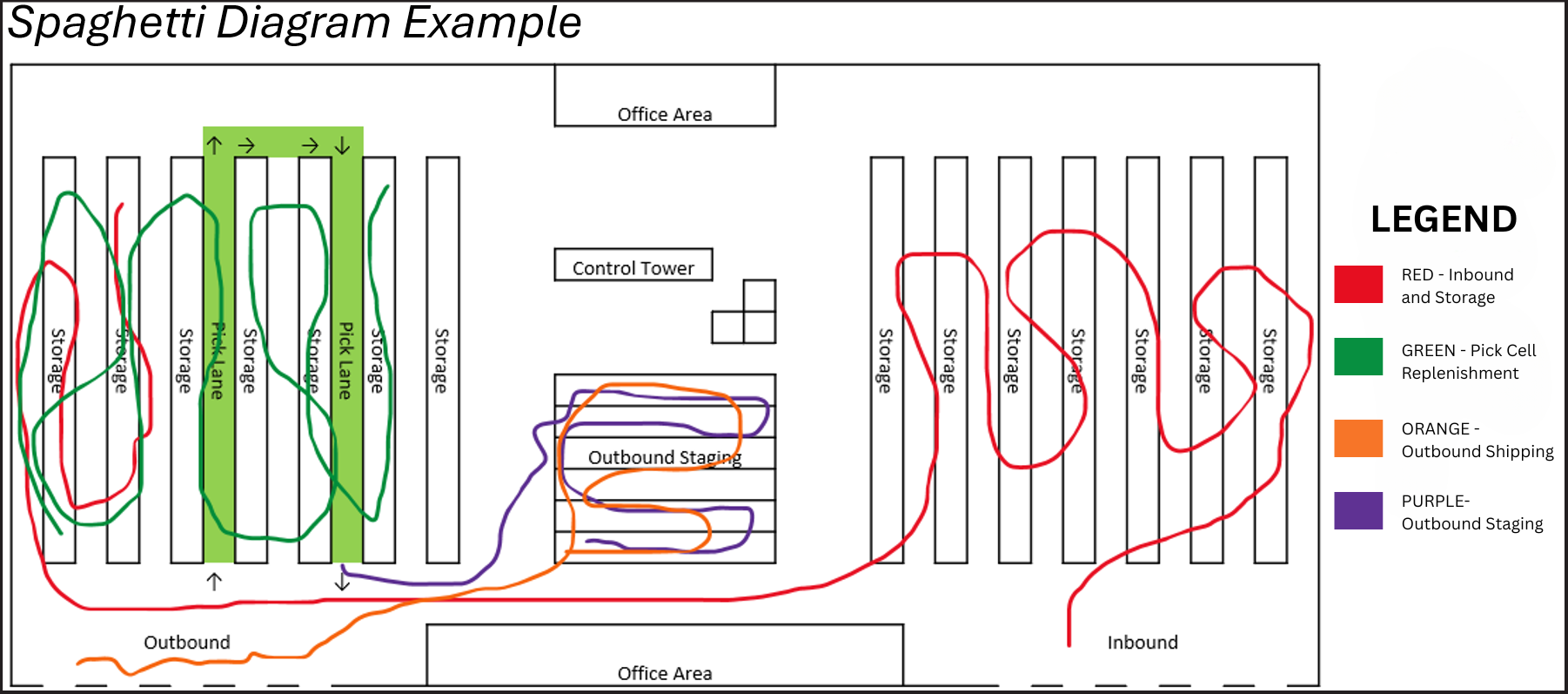

A Spaghetti Diagram is a lean tool used to visualize the flow of people, products, or information through a process or facility. Named for its resemblance to tangled spaghetti noodles, the diagram highlights inefficient movement and unnecessary travel paths in a workspace.

Purpose in Warehousing & Distribution

In warehouse and distribution environments, Spaghetti Diagrams are used to:

- Map the current flow of materials, workers, or forklifts.

- Reveal inefficiencies caused by layout design or process steps.

- Identify opportunities to shorten travel distances and streamline operations.

- Support continuous improvement and lean initiatives.

Common Uses:

- Tracking how far pickers travel during order fulfillment

- Analyzing forklift paths for staging and loading

- Studying the path of a product from receiving to shipping

- Visualizing operator movements at packing or kitting stations

How to Create One:

- Choose a process or area – e.g., order picking or shipping.

- Observe and record actual movement (don’t rely on SOPs).

- Draw lines over a facility layout to represent the paths taken.

- Analyze for waste – look for loops, backtracking, excessive travel.

- Redesign – propose layout or process improvements to reduce movement.

Benefits:

✔ Improves layout design for better flow

✔ Reduces motion waste and walking time

✔ Enhances safety by minimizing cross-traffic

✔ Leads to faster throughput and lower labor costs

Key Tip:

Combine Spaghetti Diagrams with time studies to fully understand the cost of inefficient movement and justify changes.